Very Narrow Aisle Pallet Rack

Very Narrow aisle pallet rack (VNA) A shelf rack system that evolves from a standard pallet rack system. The narrow aisle pallet rack (VNA) system requires a special narrow aisle forklift and forklift guidance system; a fairly level ground is required; in order to ensure accurate pallet access and positioning on high-level cargo locations, the forklift must be equipped with a semi-automatic auxiliary pallet positioning device; Structural strength and tolerance coordination are extremely strict, and precise design and installation must be considered comprehensively; unless low ground rails or magnetic guidance systems are used, VNA shelve racks need to be equipped with bottom beams, and trays cannot be placed directly on the ground….

1.Product Introduction:

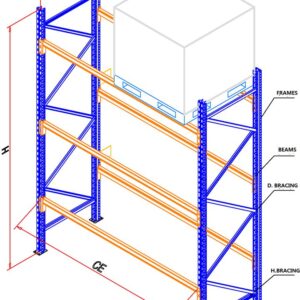

Very Narrow aisle pallet rack (VNA) A shelf rack system that evolves from a standard pallet rack system. The narrow aisle pallet rack (VNA) system requires a special narrow aisle forklift and forklift guidance system; a fairly level ground is required; in order to ensure accurate pallet access and positioning on high-level cargo locations, the forklift must be equipped with a semi-automatic auxiliary pallet positioning device; Structural strength and tolerance coordination are extremely strict, and precise design and installation must be considered comprehensively; unless low ground rails or magnetic guidance systems are used, VNA shelve racks need to be equipped with bottom beams, and trays cannot be placed directly on the ground.

2. Production Features:

Compared with the conventional pallet racking system, Very Narrow aisle pallet rack is different in that the laneway width of the narrow laneway pallet racking system is much smaller than the conventional pallet racking system, generally about 1600-2000mm, and the space utilization rate is improved. It is about 20%. In addition, guide rails must be set on both sides of the aisle for the purpose of guiding the three-way forklift.

Very Narrow aisle pallet rack is an important part of the rapid development of modern logistics systems. It has the advantages of saving land, reducing labor intensity, eliminating errors, improving the level of warehouse automation and management, improving the quality of management and operators, reducing storage and transportation losses, and effectively Many advantages such as reducing the backlog of logistics funds, improving logistics efficiency and corporate social efficiency are now more and more widely used in various industries.

Reviews

There are no reviews yet.